“Just an FYI: Energy consumed by the United States in one year equals the energy made by the Sun in one millionth of a second.”

- Neil Degrasse Tyson, Twitter

Climate change is the greatest environmental issue of our time, and exploring renewable energy is one way Shelburne Farms educates for a sustainable future. As astrophysicist and Director of The American Museum of Natural History’s Hayden Planetarium Neil Degrasse Tyson tweets, there is a great deal of energy out there to be harnessed.

Maybe you’ve seen the solar panels on our Farm Barn roof above the Children’s Farmyard. Maybe you even know about Green Mountain Power’s solar orchard near the Coach Barn. Recently, we’ve added information panels to both of these structures. Since you may not get to visit often, we thought we’d share some of that information with you here — and a bit more.

Between 2010 and 2011, 192 solar panels were installed on the south-facing pitch of the Farm Barn roof. They generate about a quarter of all the electricity needs of the building (8% of the Farm’s total needs). The Green Mountain Power Solar Orchard, also installed in 2010, contains 530 panels, allowing for another 30% of the Farm’s total electricity to be derived from the sun. In the same field near the Coach Barn, look out for the “Tracker” solar panel: an even more specialized piece of equipment that rotates over the course of the day to follow the sun’s movement across the sky (think of a daisy swiveling its stem from dawn to dusk to face the sun). Trackers produce up to 40% more electricity per square foot of panel, but require more space than stationary solar panels, because their moving shadows cover a greater land area.

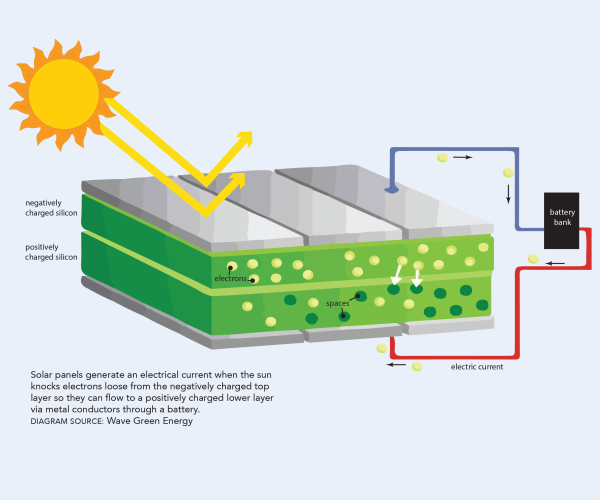

How do solar panels work? Solar panels are built of photovoltaic cells that use the light energy from the sun to create electricity (“photo” means “light” and "volt" means “electricity”). Inside these cells, which are grouped into modules and then built into the panels we recognize, are two layers of impure silicon. The top layer is “doped” with impurities (typically phosphorus) to create a negative charge, and the bottom layer is doped with boron to create a positively charged area.

As sunlight – photons – hits the solar panel, some photons interact with the unstable negative top layer, sending a stream of unbonded electrons toward the positive bottom layer. But in between the layers, the mixing of electrons soon creates a diode: an energetic “hill” that only allows electrons to pass in one direction: from the bottom layer up! The top-layer electrons still want to reach the bottom layer, so they flow out a wire circuit, which captures the electron stream and converts it into energy we can use — electricity. (See graph)

Initially, the flow of electrons is a direct current (DC) and needs to be converted to alternate current (AC). Built-in "inverters" do this work (our solar orchard has 18 of them, servicing all 530 panels). The AC current runs through a nearby transformer, is shuttled underground to the main line, and sent out to the nearest facility requiring power.

In addition to solar energy, the Farm gets about 25% of its total energy needs from biomass in the form of wood chips (18%), firewood (5%) and wood pellets (2%). The Farm Barn combusts all of the chips in a gasification furnace to heat water. Most of it heats the building from November through April, with a portion of it used to warm the milk in the vat for cheesemaking. Two miles of pipes embedded in concrete underneath the floors distributes the water throughout most of the building — a system called radiant heat. (Conventional radiators are used where a concrete floor is impractical). Depending on the winter, the Farm Barn uses between 180 and 240 tons of wood chips, which are made from waste at a nearby sawmill in Bristol, VT. With the purchase of our own wood chipper, we now can turn our own scrap wood into chips to supply a portion of the fuel. The system is deemed renewable because the forests on the property are sustainably managed with the utmost care by the Woodlands Team.

Interested in learning more about how Shelburne Farms educates for a sustainable future? Educator Ryan Morra shares his thoughts on addressing climate change through education in his article here. For more information about the science behind capturing solar energy check out NOVA and How Stuff Works.